PVC foaming regulator

Product Features

Classification: Products

Product Details

Properties

* PVC foaming regulator is a type of acrylic processing aid that possesses all the characteristics of PVC processing aids. Its molecular weight is much higher than that of general processing aids, and it has high melt strength, which can give products a more uniform cell structure and lower density.

* PVC foam regulator is widely used in PVC foam boards, foam pipes, foam profiles, as well as pipes, fittings, profiles, etc.

Technical Index

| Model/Specifications | Appearance | Apparent density (g/cm ³) | Volatile matter (%), ≤ | 30 target screening pass rate (%), ≥ | Intrinsic viscosity n, (25 ° C) |

| HF-921 | White Powder | 0.45±0.10 | 1.50 | 98 | 13.00-15.00 |

| HF-90 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.50-14.50 |

| HF-901 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.50-14.50 |

| HF-533 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.50-14.50 |

| HF-80 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.00-14.00 |

| HF-900 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.00-14.00 |

| HF-910 | White Powder | 0.45±0.10 | 1.50 | 98 | 11.00-13.00 |

| HF-911 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.50-14.50 |

| HF-715 | White Powder | 0.45±0.10 | 1.50 | 98 | 11.00-13.00 |

| HF-825 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.00-14.00 |

| HF-915 | White Powder | 0.45±0.10 | 1.50 | 98 | 12.00-14.00 |

| HF-100-1 | White Powder | 0.45±0.10 | 1.50 | 98 | 11.00-13.00 |

| HF-100-2 | White Powder | 0.45±0.10 | 1.50 | 98 | 11.00-13.00 |

| HF-100-3 | White Powder | 0.45±0.10 | 1.50 | 98 | 11.00-13.00 |

Application

| Model/Specifications | Characteristic | Application |

| HF-921/HF-90 HF-901/HF-911 | The ultra-high molecular weight and super strong melt strength endow the product with lower density and uniform pore structure, especially suitable for PVC foam thick plate products. | Suitable for various foam products, wood plastic products, especially suitable for bathroom boards, cabinet boards, thick building templates, etc |

| HF-533/HF-80 HF-900/HF-825 | Endow the product with a uniform pore structure, high molecular weight and melt strength, lower product density, and excellent processing performance. | Suitable for various foam products, wood plastic products, especially suitable for various shoe materials, special materials, etc |

| HF-910 HF-715/HF-915 | Good plasticizing ability, excellent melt flowability, and good compatibility with PVC products make the product size more stable. | Suitable for various foam products, wood plastic products, especially suitable for various wood plastic flooring, wall panels, etc |

| HF-100-1/HF-100-2 HF-100-3 | Superior plasticizing performance endows the product with excellent processing performance and surface glossiness. | Suitable for various foam products, wood plastic products, especially suitable for various wood plastic boards, wall panels, advertising boards, low foam boards, etc |

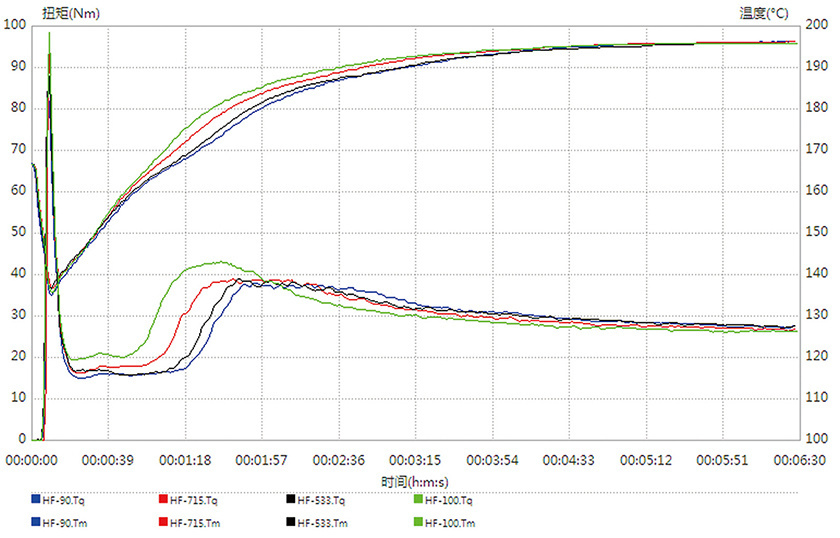

Processability

Note: The rheological diagram is only used for comparing the differences in product processing performance under the same conditions.

| Category | Plasticization time (S) | Minimum torque (Nm) | Maximum torque (Nm) | Balance torque (Nm) |

| HF-90 | 112 | 15.7 | 38.4 | 27.5 |

| HF-533 | 105 | 15.8 | 38.7 | 27.0 |

| HF-715 | 97 | 16.1 | 39.2 | 26.8 |

| HF-100 | 85 | 19.6 | 44.9 | 26.1 |

Enterprise plant

Factory building

Factory building

Factory building

Factory building

Online message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!