PVC lubricating processing aid

Product Features

Classification: Products

Product Details

Properties

* Lubricating processing aid is a kind of low molecular weight product with a certain molecular weight distribution, which is obtained by one or several acrylate monomers synthesized through lotion polymerization process, and special molecular weight regulator is added in the lotion polymerization process, so that it has good internal lubrication performance.

* The biggest advantage of lubricating processing aids is their good compatibility with PVC resin, which can completely replace various internal lubricants with poor compatibility with PVC resin. Lubricating processing aids have both external sliding and processing properties, and their acrylic processing can provide both external sliding performance and avoid the problem of poor compatibility caused by lubricants. At the same time, they provide excellent plasticizing and additive properties, significantly improving the quality of PVC products, shortening processing time, and improving production efficiency.

Technical Index

| Model/Specifications | Appearance | Apparent density (g/cm ³) | Volatile matter (%), ≤ | 30 target screening pass rate (%), ≥ | Intrinsic viscosity n, (25 ° C) |

| HF-175 | White Powder | 0.45±0.10 | 1.50 | 98 | 1.00-3.00 |

| HF-176 | White Powder | 0.45±0.10 | 1.50 | 98 | 0.50-1.50 |

Application

| Model/Specifications | Characteristic | Application |

| HF-175 | Has internal and external lubricant and processing aid properties, no precipitation, improves product flowability, and has excellent metal stripping properties. | The product is suitable for various processes such as hard PVC sheets, pipes and fittings, profiles, foam boards, etc |

| HF-176 | It has excellent metal stripping properties, excellent internal and external lubrication effects, excellent product flowability, prolonged machine operation time during processing, and no precipitation. | Specially suitable for various processes of hard PVC processing, such as films, sheets, pipes, fittings, profiles, foam boards, etc |

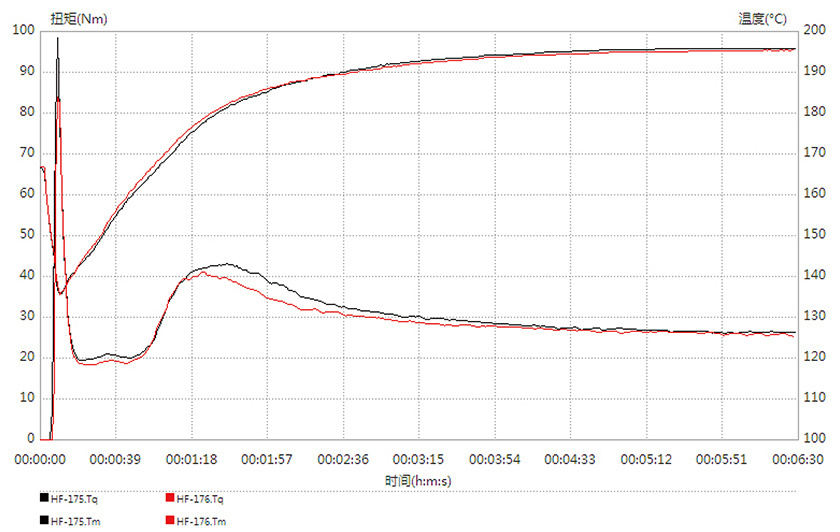

Processability

Note: The rheological diagram is only used for comparing the differences in product processing performance under the same conditions.

| Category | Plasticization time (S) | Minimum torque (Nm) | Maximum torque (Nm) | Balance torque (Nm) |

| HF-175 | 75 | 19.6 | 44.9 | 26.1 |

| HF-176 | 73 | 18.4 | 4.8 | 25.3 |

Enterprise plant

Factory building

Factory building

Factory building

Factory building

Online message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!