PVC impact modifier (ACR)

Product Features

Classification: Products

Product Details

Properties

* Impact modifier is an acrylic ester based impact modifier with a "core-shell" structure. Its core is a lightly crosslinked acrylic ester copolymer, and its shell is a methyl methacrylate copolymer, which has good compatibility with PVC. When subjected to external impact, the rubber core changes, causing the generation of silver lines and shear bands, absorbing impact energy, and exhibiting excellent impact resistance, weather resistance, and color durability under long-term outdoor exposure conditions.

* Acrylic impact modifiers are widely used in various transparent and non transparent products such as profiles, profiles, pipes, fittings, plates, films, wood plastic, etc.

Technical Index

| Model/Specifications | Appearance | Apparent density (g/cm ³) | Volatile matter (%), ≤ | 30 target screening pass rate (%), ≥ | Glass transition temperature TG, (° C) |

| HF-K01 | White Powder | 0.45±0.10 | 1.50 | 98 | -40±2 |

| HF-K02 | White Powder | 0.45±0.10 | 1.50 | 98 | -38±2 |

| HF-K03 | White Powder | 0.45±0.10 | 1.50 | 98 | -50±2 |

Application

| Model/Specifications | Characteristic | Application |

| Universal HF-K01 | Good low-temperature impact performance and excellent weather resistance. | Mainly used in the field of PVC profiles, pipes, fittings, sheets, films and other PVC ordinary products |

| Transparent HF-K02 | Good low-temperature impact performance, high light transmittance, can endow products with good surface glossiness. | Mainly used in transparent products such as PVC sheets, boards, films, etc |

| High impact resistance HF-K03 | Superior low-temperature impact performance can endow products with good dimensional stability. | Mainly used in the field of PVC high toughness and high impact products such as PVC profiles, pipes, fittings, sheets, films, etc |

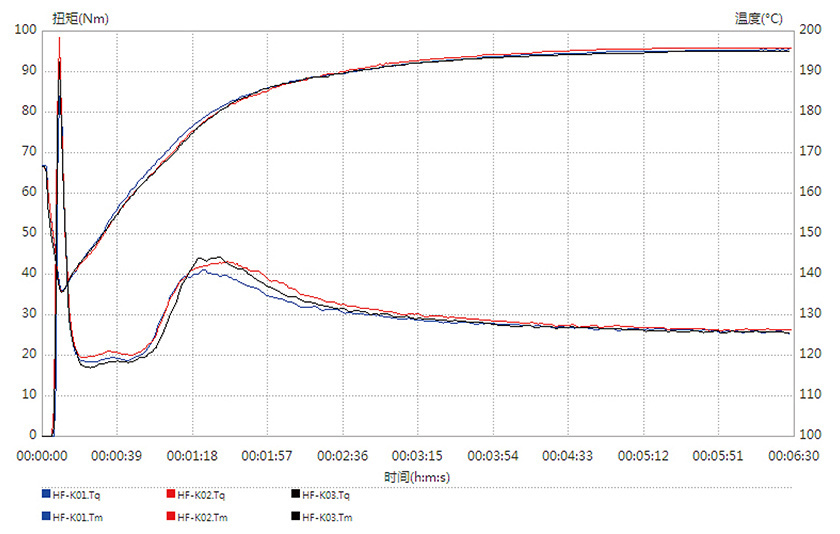

Processability

Note: The rheological diagram is only used for comparing the differences in product processing performance under the same conditions.

| Category | Plasticization time (S) | Minimum torque (Nm) | Maximum torque (Nm) | Balance torque (Nm) | Impact strength (KJ/m²) | Tensile elongation at break (%) | Vicat softening point (℃) | Shore hardness (A) |

| HF-K01 | 110 | 14.9 | 36.4 | 25.7 | 21.5 | 1223.1 | 82.5 | 82.3 |

| HF-K02 | 113 | 15.4 | 37.1 | 26.1 | 21.3 | 122.9 | 82.5 | 82.4 |

| HF-K03 | 121 | 14.1 | 40.4 | 25.7 | 21.8 | 127 | 82.3 | 82.1 |

Enterprise plant

Factory building

Factory building

Factory building

Factory building

Online message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!